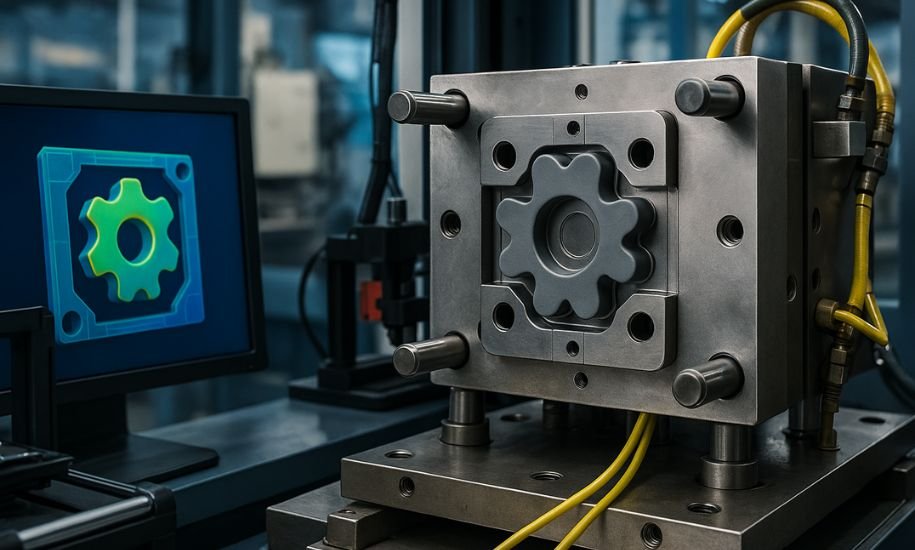

What is Repmold ?- The Rapid Moulding Revolution

In today’s rapidly changing manufacturing world, a new concept is quietly transforming how products are designed, prototyped, and produced — repmold. The term, derived from “replication” and “mould,” refers to a method that fuses digital design, additive manufacturing, and high-precision mould replication to achieve faster production, lower costs, and improved sustainability. As industries push for speed, quality, and flexibility, repmold is becoming a symbol of the next manufacturing revolution.

What is Repmold?

Repmold is not a single machine or a brand—it’s a methodology. It blends traditional moulding principles with rapid, repeatable digital processes. In simple terms, it’s the creation of moulds through digitally guided replication, using advanced tools like CAD software, 3D printing, CNC machining, and real-time simulation. The goal is to produce moulds faster, cheaper, and more precisely than conventional methods allow.

In a repmold workflow, the design is fully digital, allowing engineers to simulate and test before any material is cut. Once verified, rapid tooling—often through additive manufacturing or high-speed CNC—produces the mould or its inserts. This mould can then be used in injection, compression, or blow moulding, enabling quick production of high-quality parts. The defining feature is repeatability: once perfected, the mould design can be replicated swiftly whenever needed.

Repmold isn’t just a new term; it’s an approach that captures the spirit of modern manufacturing—precision, iteration, and digital flexibility.

How Repmold Works

A typical repmold process unfolds in several integrated stages:

-

Digital Design and Simulation:

Engineers begin by creating a detailed 3D model using CAD/CAE software. They simulate the moulding process—tracking filling, cooling, shrinkage, and warpage—to detect flaws early. This virtual step drastically reduces the need for multiple prototype revisions later. -

Rapid Tooling and Mould Production:

Instead of traditional tool-steel fabrication that can take months, repmold employs 3D-printed or CNC-machined moulds made from specialized polymers, resins, or hybrid composites. These tools are ready in days and can produce fully functional parts for testing or short-run production. -

Moulding and Production:

The rapid-tooled mould is used in injection, compression, or blow moulding machines to form the desired parts. Because the design and tooling were validated digitally, the first physical run often produces accurate, usable results. -

Iteration and Replication:

Once a mould is validated, it can be replicated quickly for additional production lines or design variations. If product updates are required, engineers simply adjust the digital model and reprint or machine a new version—making the process agile and cost-effective.

Why Repmold Matters

Repmold exists at the intersection of three critical manufacturing demands: speed, cost efficiency, and sustainability.

-

Speed:

Traditional moulding relies on long lead times—design, machining, testing, rework. Repmold compresses these steps into a digital loop, allowing new designs to move from concept to part in a fraction of the time. -

Cost Efficiency:

Tooling costs are often the biggest barrier to product innovation. Repmold minimizes this by using rapid tooling and modular inserts that can be modified or reused. This makes small-batch or custom production economically viable, especially for startups and agile manufacturers. -

Sustainability:

Many repmold processes use recyclable materials for tooling and generate less waste overall. Modular tool components and shorter production cycles also reduce energy consumption and carbon footprint. It’s a step toward cleaner, leaner production systems that align with modern sustainability goals.

Key Benefits of Repmold

Companies adopting repmold frequently report major improvements in several areas:

-

Enhanced Accuracy and Consistency:

Digital design ensures that each mould is geometrically precise and identical to the next. This reduces dimensional variation and improves product quality. -

Faster Iteration Cycles:

When a design tweak is needed, the updated mould can be re-produced almost immediately. This speed enables real-time innovation and rapid market response. -

Reduced Risk in New Product Launches:

By testing prototypes and pilot runs with repmold tools, engineers can catch design flaws early, avoiding costly errors in full production. -

Flexibility for Small or Medium Runs:

Traditional steel tooling only makes sense for large-volume production. Repmold allows cost-efficient production even at smaller scales, unlocking new possibilities for customisation and limited-edition manufacturing. -

Sustainable Operations:

By cutting material waste, reusing inserts, and reducing energy input, repmold contributes to the circular manufacturing movement—less waste, more efficiency.

Industries Leading with Repmold

Repmold’s versatility makes it attractive across multiple sectors:

-

Automotive:

Used for rapid prototyping of components, lightweight parts, and custom assemblies. Manufacturers can test new designs quickly without full-scale tooling investment. -

Medical and Healthcare:

Ideal for complex shapes and precision instruments that require small batches or frequent updates due to evolving regulations and designs. -

Consumer Electronics:

The fast design cycles and high precision of repmold make it perfect for smartphones, wearables, and electronic casings where style and performance must align. -

Aerospace:

High-value components, demanding specifications, and limited-volume production benefit from the flexibility and material efficiency of repmold workflows. -

Industrial Equipment and Consumer Goods:

From prototypes to end-use parts, repmold helps businesses bring innovative designs to market faster than ever.

Challenges and Considerations

Despite its many strengths, repmold also presents certain challenges:

-

Material Limitations:

3D-printed or polymer-based tooling may not withstand the same high pressures and temperatures as hardened steel. For very high-volume runs, traditional tooling remains the better choice. -

Technology Investment:

Implementing digital design systems, 3D printers, and CNC machinery requires initial investment and training. However, the long-term savings and agility often justify these costs. -

Standardisation Issues:

Since “repmold” is still a relatively new term, definitions and standards vary among manufacturers. Each company must clearly define what the concept means within its own process framework. -

Scalability:

While ideal for short and medium production runs, companies must evaluate at what volume repmold ceases to be the most cost-effective option compared to conventional tooling.

The Future of Repmold

Looking ahead, the next evolution of repmold will likely involve greater integration with artificial intelligence, smart sensors, and automated quality control. Imagine moulds embedded with sensors that detect flow issues in real time, or AI software that adjusts designs automatically to prevent defects before production begins.

Future repmold systems could also merge with the Internet of Things (IoT), enabling factories to share digital mould data across multiple sites worldwide. When a new part is approved, identical moulds could be replicated instantly in different regions—streamlining global production while maintaining exact consistency.

In this way, repmold is more than a process; it’s a bridge between traditional manufacturing and fully digital, autonomous production systems.

Why Businesses Should Pay Attention

For companies engaged in manufacturing, product design, or prototyping, understanding repmold is essential. It offers a pathway to:

-

Faster development and shorter time-to-market

-

Lower tooling investment and reduced financial risk

-

Greater design freedom and customisation

-

Smaller environmental impact and improved efficiency

Even for organisations not yet ready to adopt full digital tooling, embracing repmold principles—like simulation-first design, modular mould components, or hybrid additive tooling—can create a significant competitive edge.

Final Thoughts

Repmold represents the next frontier in mould-making and manufacturing. It unites digital precision, rapid prototyping, and sustainability into one cohesive framework. As industries continue to demand speed, flexibility, and eco-friendly solutions, repmold stands out as a game-changing approach for the 21st century.

For those willing to evolve, it’s more than a method—it’s a mindset. A mindset that values iteration, innovation, and efficiency over rigidity. The companies that adopt repmold today will likely define the manufacturing standards of tomorrow.

At American Times, we believe the rise of repmold signals a profound transformation in how products are imagined and built. It’s not just a trend—it’s the foundation of a smarter, faster, and greener manufacturing future.